CIPP - HEAT

After a polyester-based fabric (liner) is impregnated into the duct (addition of some resin and chemical additives), it is drawn into the existing pipeline, The hose-shaped fabric is inflated and stretched, It is heated and hardened by curing with hot water/steam. CIPP–PARCELE CONNECTION / LINING TECHNOLOGY

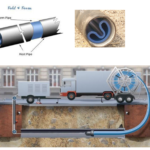

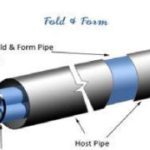

FOLD & FORM

The HDPE/PVC lining, which is wrapped on a reel, is placed between the two existing manholes with the help of a mobile crane. Then, by heating the lining with steam, the lining pipe is expanded (taking the shape of a circular section) and the inner surface of the existing pipes is re-lined. DN100- DN450

CIPP - UV

It is the process of placing a resin-impregnated glass fiber braided liner between two existing manholes and curing it with Ultraviolet (UV) light to tightly wrap the existing pipe inner wall. DN150-DN1800

Why Rehabilitation?

Reinforces the pipeline from beginning to end as a single piece. Broken, cracked, leaking and leaking at pipe connection points are prevented. Reduces friction, increases flow rate. Rust is completely eliminated. Pipe slip and shift ends. Long-lasting, has a 50-year service life. Due to the flexibility of the materials, it is resistant to blows from above, earthquakes and landslides. It does not require excavation and excavation; does not create dust/soil pollution. It prevents infiltration and exfiltration, and the revival of the soil accelerates. It progresses quickly, and a lot of meters are done in a short time. It does not block traffic flow. It does not disturb the environment; does not create noise pollution. It is economical.